THAILAND'S MOST ADVANCED WEEL HUB MANUFACTURING FACILITY

Our Factory

LOREM

LOREM

Lorem ipsum dolor sit vivid amet, elit.

LOREM

LOREM

Lorem ipsum dolor sit vivid amet, elit.

LOREM

LOREM

Lorem ipsum dolor sit vivid amet, elit.

LOREM

LOREM

Lorem ipsum dolor sit vivid amet, elit.

Brand New Manufacturing Line as of 2023

State of the

Art Assembly Line

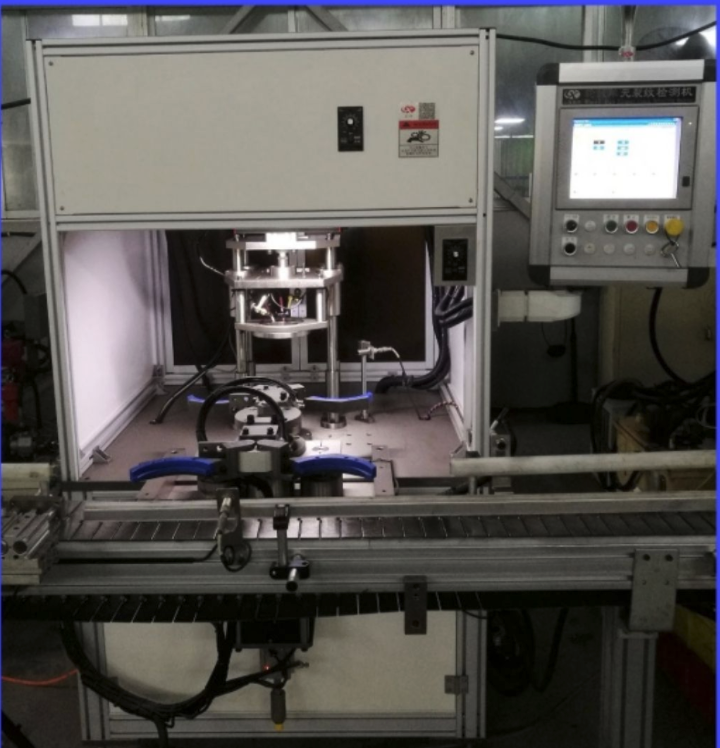

Gen 3 TRB Automatic Assembly Line

The Gen 3 TRB Automatic Assembly Line represents the latest advancement in high-precision, high-efficiency manufacturing for tapered roller bearings (TRBs). This third-generation system showcases innovations in automation, digital integration, and quality control, enhancing production throughput while maintaining exceptional consistency.

Key Features

- Full Automation: The line incorporates robotic handling, automated inspection, and inline lubrication and packaging systems to minimize human intervention and reduce error rates.

- Smart Integration: It is equipped with Industrial IoT (IIoT) sensors, real-time data analytics, and machine learning algorithms for predictive maintenance and continuous process optimization.

- High Throughput & Flexibility: Capable of handling multiple TRB variants, the system can rapidly switch between production modes, reducing downtime and boosting responsiveness to market demand.

- Quality Assurance: Inline inspection stations with high-resolution cameras and precision metrology systems ensure that each unit meets strict dimensional and performance standards.

Quality Control

Industry leading Quality

Control

Automated Quality Control

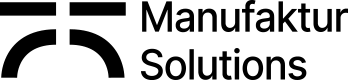

To uphold the highest standards of product integrity and performance, our facilities are equipped with a comprehensive suite of state-of-the-art testing and diagnostic instruments. Each tool is purposefully selected to evaluate critical material, dimensional, and functional characteristics across various manufacturing stages.

Key Equipment and Their Functions

- MMDR Profile Reader: Measures minute variations in the dimensional profile of components, ensuring geometric precision and adherence to tolerance specifications.

- Hardness Tester: Assesses material hardness using Rockwell, Vickers, or Brinell scales, crucial for verifying heat treatment consistency and mechanical resilience.

- Roughness Profile Analyzer: Evaluates surface finish characteristics to ensure optimal friction behavior, wear resistance, and seal compatibility.

- Steel Material Analyzer: Identifies and validates the chemical composition of steel alloys using spectrometry, safeguarding against material non-conformance.

Testing

Progressive Stress, Speed,

and Load Testing Capabilities

Testing

Our Progressive Stress, Speed, and Load Testing Capabilities are engineered to replicate extreme real-world operating conditions—enabling us to validate product reliability, endurance, and performance over the full lifecycle. By simulating escalating levels of mechanical stress, rotational speed, and load, we identify thresholds, optimize designs, and ensure uncompromising durability.

Key Equipment and Their Functions

- Load Simulation Equipment: Replicates real-world mechanical loads to assess the durability, fatigue resistance, and deformation behavior of components under stress.

- Eddy Current Crack Detection Equipment: Uses non-destructive eddy current methods to detect subsurface cracks and material discontinuities in conductive materials.

- ABS Speed Sensor Tester: Validates the functionality and signal accuracy of ABS speed sensors to ensure vehicle safety and compliance with automotive standards.

- End-Play Testing Equipment: Measures axial movement (end-play) in assembled units, critical for ensuring proper bearing preload and mechanical performance.

Manufacturing Capabilities

OUr Equipment

OUr Equipment

OUr Equipment

OUr Equipment

Quality Control Equipment

MMDR Profile Reader

Hardness Testor

Roughness Profile Analyzer

Steel Material Analyzer

Load Simulation

Eddy Crack Equipment

ABS SPeed Sensor TestEr

End-Play Testing Equipment

Our Location

Thailand's Premier Industrial

District

In the Heart of Thailand's largest industrial district

Strategically located in the core of Thailand’s largest industrial district, our operations benefit from proximity to the country's most vital manufacturing ecosystem. This premier location provides unparalleled access to a robust supply chain, skilled labor force, and world-class infrastructure.

Our Shipping Capabilities

Direct Access to

Ports

Seamless Global Connectivity

Our facility’s direct access to major deep-sea and inland ports ensures highly efficient logistics, reduced transit times, and competitive export advantages. This strategic positioning enables swift, cost-effective movement of raw materials and finished goods to and from international markets.

Logistics Advantages

- Proximity to Major Gateways: Located within a short haul of Thailand’s key ports, including Laem Chabang and Bangkok Port, enabling same-day dispatch and receipt of shipments.

- Streamlined Export Processes: Close collaboration with customs and logistics hubs allows for faster clearance, minimized delays, and optimized freight scheduling.

- Multimodal Transport Links: Integrated road, rail, and sea connectivity supports flexible, scalable logistics operations tailored to customer needs.

OUR PRODUCTS

Parts shipped each year

New SKU's Added Each Year